Congratulations to “2024 Coal-fired Power Plant Safety, Environmental Protection, Quality and Efficiency Improvement Technology Exchange Seminar” a complete success!

March 29-30, 2024,The Technical Exchange Seminar on Safety, Environmental Protection, Quality Improvement and Efficiency Enhancement of 2024 Coal-fired Power Plants was successfully held in Jiangmen City. The seminar was jointly hosted by the China Energy and Environment Union Energy Technology Innovation Service Center, the National Power Generation Enterprise Cooperation Network, and the National Electric Power Industry Cooperation Network, with Pourin Special Welding Technology Co., Ltd. as the co-organizer.

The theme of the conference was "Promoting Clean, Efficient, Flexible, Low-Carbon, and Intelligent High-Quality Development of Coal Power," where representatives from power generation groups, thermal power plants, and research institutes from all over the country gathered to discuss new trends and technologies in the coal power industry, and to promote green and low-carbon transformation and quality improvement. At the meeting, Li Haisheng, the general manager of Pourin Special Welding Technology Co., Ltd., delivered a technical presentation titled "The Main Causes of Corrosion in Power Generation Boiler Membrane walls and Preventive Measures." He first presented the current corrosion conditions of power generation boilers, explained in detail the reasons for boiler corrosion and tube ruptures, and described the technical principles and characteristics of membrane walls cladding technology, as well as showcasing some of our company's achievements and construction cases in Xinjiang, Shandong, Hunan, and Hubei.

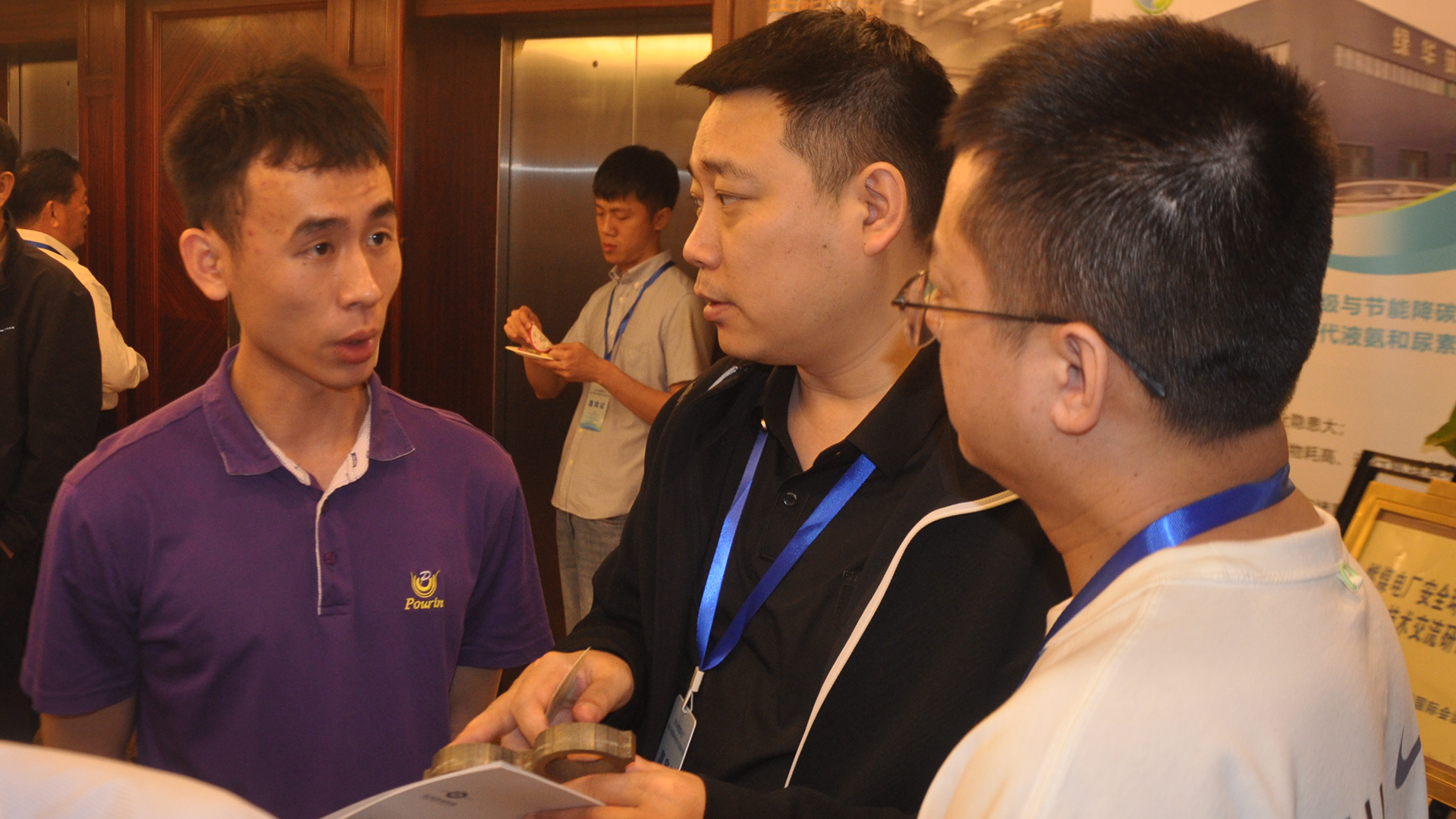

At the meeting, Li Haisheng, the general manager of Pourin Special Welding Technology Co., Ltd., delivered a technical presentation titled "The Main Causes of Corrosion in Power Generation Boiler Membrane walls and Preventive Measures." He first presented the current corrosion conditions of power generation boilers, explained in detail the reasons for boiler corrosion and tube ruptures, and described the technical principles and characteristics of membrane walls cladding technology, as well as showcasing some of our company's achievements and construction cases in Xinjiang, Shandong, Hunan, and Hubei.  During the seminar, representatives from several power plants came to the POURIN’s booth for in-depth discussions on Membrane wall cladding technology for anti-corrosion and anti-erosion , and expressed their intention to cooperate.

During the seminar, representatives from several power plants came to the POURIN’s booth for in-depth discussions on Membrane wall cladding technology for anti-corrosion and anti-erosion , and expressed their intention to cooperate.  The following day, our company invited representatives from power generation groups, thermal power plants, and research institutes to visit our company, allowing them to gain a deeper understanding of our company's processes and products.

The following day, our company invited representatives from power generation groups, thermal power plants, and research institutes to visit our company, allowing them to gain a deeper understanding of our company's processes and products. In the future, Pourin Special Welding Technology Co., Ltd. will continue to focus on the technology of anti-corrosion and anti-erosion for boiler membrane walls, providing customers with more cost-effective anti-corrosion and anti-erosion solutions, and growing together with the industry! We will do our utmost, guided by technology, to provide customers with satisfactory products through low-cost and efficient management methods!

In the future, Pourin Special Welding Technology Co., Ltd. will continue to focus on the technology of anti-corrosion and anti-erosion for boiler membrane walls, providing customers with more cost-effective anti-corrosion and anti-erosion solutions, and growing together with the industry! We will do our utmost, guided by technology, to provide customers with satisfactory products through low-cost and efficient management methods!

Related News

Project:Inconel overlay for SUPERHEATER tubes and HEADER tubes for Covanta US,

Project:Inconel overlay for SUPERHEATER tubes and HEADER tubes for Covanta US, overaly material is INCONEL 625, overlay thickness is 1.8 mm,overlay area is 344.5 ㎡;on time delivered on December 14th 2

Project:Inconel overlay for upper side wall and upper rear wall panels for Covanta US,

Project:Inconel overlay for upper side wall and upper rear wall panels for Covanta US, overaly material is INCONEL 625, overlay thickness is 1.8 mm,overlay area is 352 ㎡;on time delivered on January 2

Project:Superheater and reheater at Duke Energy Group's Belews Creek station in USA.

Project:Superheater and reheater at Duke Energy Group's Belews Creek station in USA. Overlay material--Inconel 622, overlay thickness--1.78mm, overlay area--2044+m2 (11330m), delivery date--Jan 26, 20

Project:Superheater and reheater of CFB boiler at Calaca station in Philippine.

Project:Superheater and reheater of CFB boiler at Calaca station in Philippine. Overlay material--Inconel 622, overlay thickness--1.78mm, overlay area--72+m2 (400m), delivery date--Nov 20, 2018.

Project:Finish superheater of biomass boiler at Forestalia Group's Cubillos station in Spain.

Project:Finish superheater of biomass boiler at Forestalia Group's Cubillos station in Spain. Overlay material--Inconel 625, overlay thickness--0.8mm, overlay area--508+m2 (2850m), delivery date--July