TECHNOLOGY

Anti-Corrosion For Non-Ferrous Smelting WHB Boiler

It mainly aims at the non-ferrous metallurgy industry, large sulfur fume can corrode the boiler in the process of melting.

In severe cases, the service life of the melting boiler will be less than a year, the rising flue will frequently leak, resulting in very serious economic losses. If high temperature sulfide resistant alloy can overlay welded.(such as the most commonly used INCONEL625) , It will significantly extend the service life of the boiler by at least 5 years,and overlay welding is a protective measure to used in domestic copper smelters.

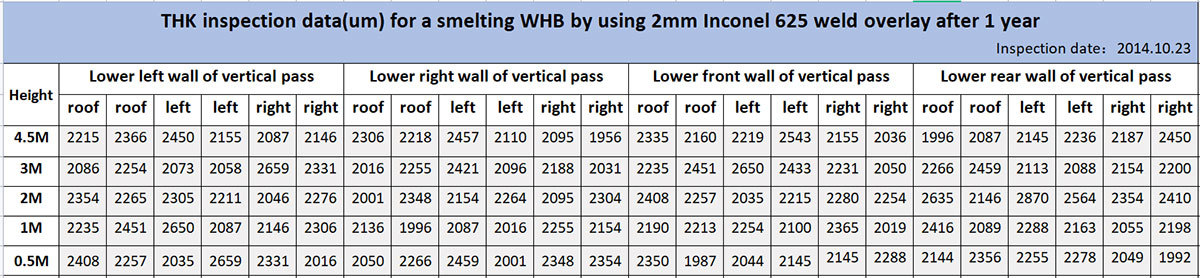

A smelting boiler after operation for 11 months ( without overlay welding), the furnace nozzel, ascending flue and boiler roof are frequently leaking due to high temperature corrosion, In September 2013, it was replaced with overlay welding (2m THK, INCO625). After one year, there was no leakage and pipe explosion in the furnace nozzel, rising flue and boiler roof. By detecting the overlay welding area, and the welding ripple of the overlay welding layer was clearly visible, with almost no corrosion.(See picture above)