TECHNOLOGY

Weld Overlay Property

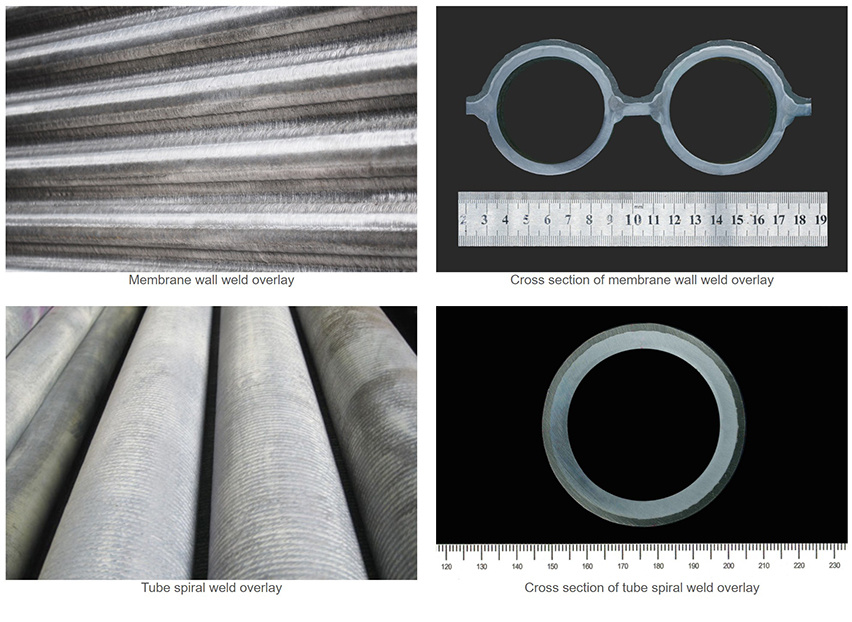

Pourin can make uniform weld overlay on tube or panel with anti-erosion and anti-corrosion material in accordance with customer's requirements. The main materials for weld overlay are Inconel622, Inconel625, ER309L, MG250, etc.

- Chemical corrosion

Boiler in operation such as Incineration boiler, Gasifier, WHB boiler, CFB boiler, due to the flue gas of the burning fuel used contains a large number of corrosive media, in the cooling area, a large number of supersaturated corrosive media will be formed, which will cause serious corrosion to the wall. It will seriously affect the boiler operation efficiency and safety. Weld overlay with Inconel625 is the best way to solve the problem. This technique has been applied in a wide range range of boilers at home and aboard.

- Abrasive erosion

The boiler waterwall shall be seriously wore and thinned under the bad working condition with the high-speed scour of the flue gas and the inferior pulverized coal. In some cases, the annual thinning amount will reach 0.8~1.2mm. After one or two years of operation, the boiler will have frequent tube explosion and maintenance. If a layer of high-strength erosion-resistant metal is overlay welded on the tube wall, the frequency of tube explosion and maintenance can be effectively reduced, and the service life of the boiler can be highly increased. This technology is mainly used in various types of power boilers and waste to energy boilers.

- High-Temperature Erosion.

The waste heat boiler's membrane wall is exposed to high temperature radiation from the flue gas of the smelting furnace (The temperature can reach 1000℃). A layer of oxide film shall be formed on the surface of membrane wall. The oxide film can be blew away quickly and at the same time the new oxide film is formed, it becomes a circular situation. Under such bad conditions, tube leakage and boiler shutdown shall be frequently occurred in a short of time (half year later) owing to the thinning of membrane wall, It will seriously affect the boiler operation efficiency and safety. If a high temperature resistant and oxidation resistant material such as Inconel 622 or Inconel 625 is overlay welded in this high temperature area, it can effectively prevent boiler tube blows up and boiler pause, the service life increased to more than 5 years. This technique has been successfully applied to the flue gas collection sites of waste heat boilers,such as Jiangxi Copper, Tongling Copper, Zhuzhou smelt in China.

In fact, during boiler operation, the thinning of tube wall is not caused by a single factor, but by the combined impact of the above three factors. With the characteristics of strong oxidation and corrosion resistance, superb strength and toughness at high temperature, and excellent machinability, Inconel 622 and Inconel 625 are usually used by customers for overlay welding under complex working conditions.