TECHNOLOGY

TECHNOLOGY

TECHNOLOGY

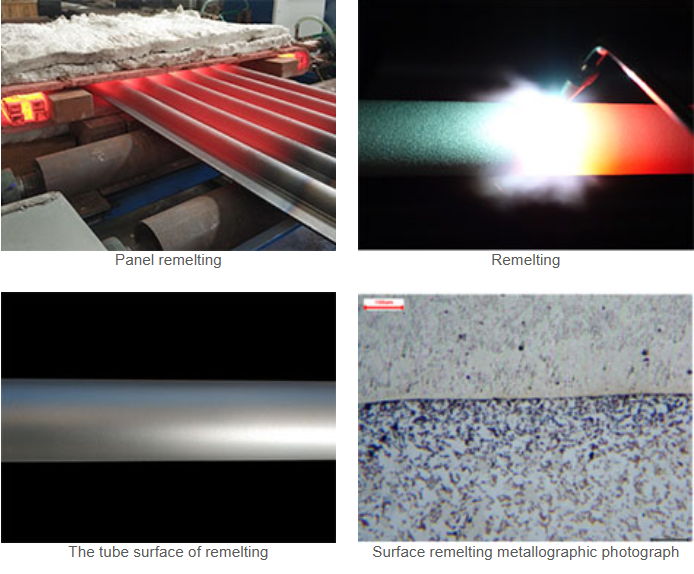

The secondary remelting technique of Pourin is a technique of remelting the flame spraying layer by using a variety of different heating methods.Secondary remelting has the advantages of high efficiency and the advantages of various processing methods.

This process can melt alloy powder, ceramic powder and other special materials on the base material surface to achieve semi-atomic metallurgical bonding, and obtain special cladding layers with zero porosity, such as nickel base/cobalt base + tungsten carbide, chromium carbide, zirconia and other special properties for high service life.

The secondary remelting can realize the thin cladding, and can choose different processing methods according to the shape of the workpiece, which is suitable for the vast majority of the workpiece.

Pourin Special Welding Technology Co., Ltd.

Address:No.8, Gongying Road, Gonghe Town, Heshan, Jiangmen City, China

Post code:529728

Tel:+86-750-8399239 +86-750-8399967

Fax:+86-750-8399230

E-mail:overseas@pour-in.com

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.

Welcome to leave a message

If you have any questions, please feel free to contact us,We will contact you as soon as possible.

Copyright©2023 Pourin Special Welding Technology Co., Ltd. Powered by www.300.cn